Emballage à paroi mince : Quand la perte de poids est un gain de durabilité

Discover the environmental benefits of thin-wall packaging: reducing weight for sustainable gains in this innovative approach.

At a Glance

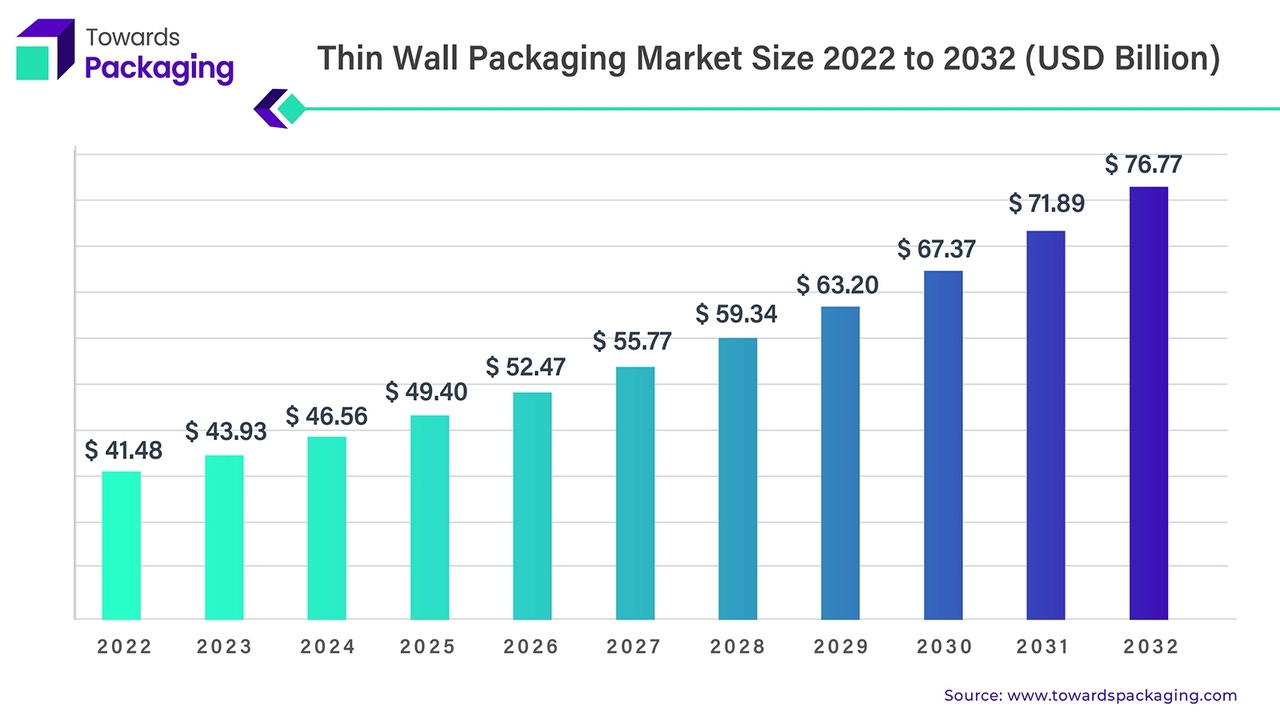

- Thin-wall packaging market is growing 6.4% yearly

- Thin-wall packaging is widely used in food and beverages, especially dairy products

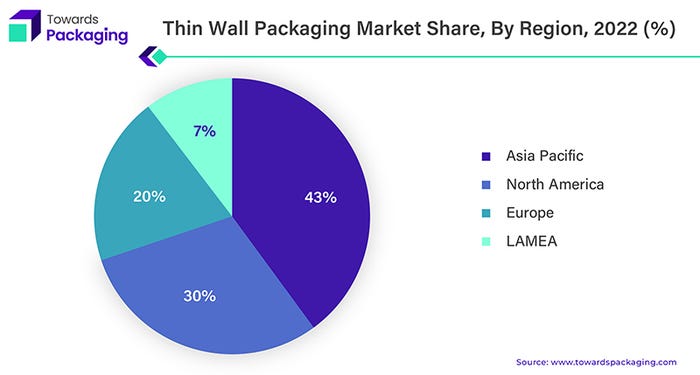

- North America dominates with 30% of the global market

Thin has been “in” for decades as one of the foundational “Four Rs” approaches to improved sustainability, reduce.

It’s a strategy seen in simplified barrier structures for flexible packaging — that typically are also recyclable — and in reduced material use in rigid containers.

It’s in rigids where one finds thin-wall packaging, which is defined by a new market report from Towards Packaging as “packaging materials characterized by a thin and lightweight design.”

Thin-wall packaging: key products and regions.

Thin-wall packaging has become ubiquitous in many industries, notably food and beverages.

For food, thin-wall packaging is extensively employed for dairy containers, including yoghurt cups, and frozen foods, fruits, vegetables, bakery items, ready meals, juices, soups, and meats.

It’s also adaptable beyond traditional applications as a replacement for glass and cans in commodities such as meat and preserves. This creates new marketing opportunities.

Two main segments stand out within the thin-wall packaging market: open-top containers and lids.

Open-top containers, a prevalent choice in this market, are commonly used for packaging frozen food or fresh food items and paint, adhesives, cosmetics, and pharmaceuticals.

From a regional view, North America’s substantial role in the thin-wall packaging market is represented by a 30% market share.

Thin-wall packaging: a caveat, news, and references.

However, before companies consider changes around thin-wall packaging, Bob Lilienfeld, executive director, SPRING, shares a cautionary note from a holistic view.

.png)

“Thin-wall packaging needs to be considered a part of an entire supply chain perspective,” the sustainable packaging expert tells us. “A typical lifecycle assessment based primarily on source reduction will make it seem like the right decision. But if increased product breakage or spillage occurs, either because the package is no longer strong enough, or secondary packaging such as paperboard cartons can no longer protect the primary package without a fiber/weight increase, thin walling is probably the wrong answer.”

Hygintek’s aluminum thin-wall bottles are not only known for their durability, convenience, and sustainability but also for their exceptional customizability. We take pride in offering a wide range of customization options to meet your specific packaging requirements. Whether you need unique shapes, sizes, or branding elements, our team of dedicated product specialists is ready to assist you. Contact us today to experience our unrivaled customizability and benefit from the expertise of our professionals who will provide prompt and tailored responses to your inquiries.

À propos de nous

Hygintek est un fabricant de premier plan d'emballages métalliques durables et respectueux de l'environnement pour les produits alimentaires et les boissons, les médicaments et les marques saines, leur offrant une solution d'emballage et un service tout-en-un.

CONTACTEZ-NOUS

Postes récents

-

Bouteille de boisson énergétique

Bouteille de boisson énergétique -

Bouteille de boisson à paroi mince

Bouteille de boisson à paroi mince -

Moins de 30 jours ! Cosmoprof CBE Asean Bangkok 2024 arrive !

Moins de 30 jours ! Cosmoprof CBE Asean Bangkok 2024 arrive ! -

Nouveaux pots en aluminium disponibles

Nouveaux pots en aluminium disponibles -

Moins de 30 jours ! Cosmoprof CBE Asean Bangkok 2024 arrive !

Moins de 30 jours ! Cosmoprof CBE Asean Bangkok 2024 arrive ! -

Applications des bombes aérosols : Domaine pharmaceutique

Applications des bombes aérosols : Domaine pharmaceutique -

Bouteilles à capsules en aluminium : Le premier choix pour des solutions d'emballage innovantes

Bouteilles à capsules en aluminium : Le premier choix pour des solutions d'emballage innovantes -

Boîtes en aluminium écologiques et polyvalentes

Boîtes en aluminium écologiques et polyvalentes -

Les héros de tous les jours : L'action environnementale des clients

Les héros de tous les jours : L'action environnementale des clients -

Un accueil chaleureux pour les clients VIP chez Hygintek

Un accueil chaleureux pour les clients VIP chez Hygintek

.jpg)