Automated Production: Aluminum Capsule Bottles Now Available

We are pleased to introduce a new design of our aluminum capsule bottle line that has achieved a technological breakthrough and is manufactured using a fully automated production line.

What is an automatic line?

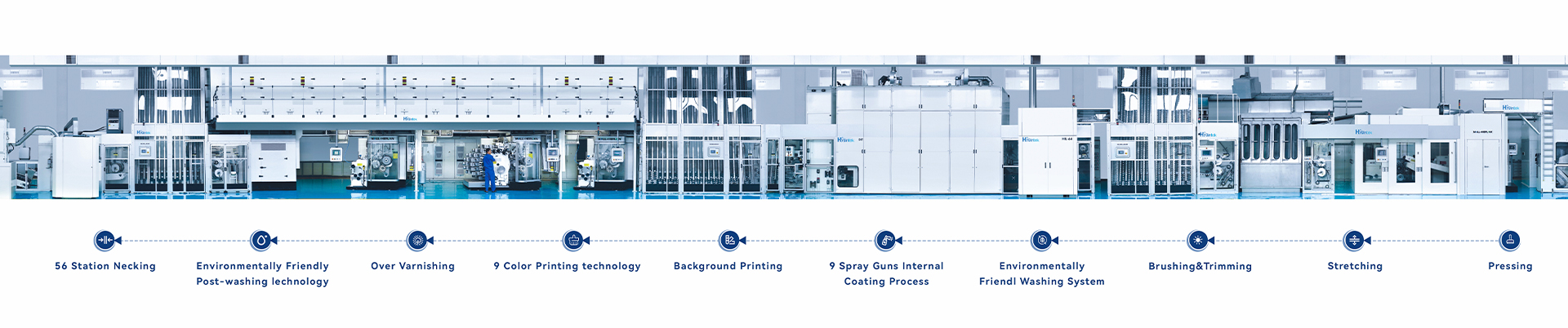

Automatic line aluminum bottles use automated production equipment for tasks like spraying, shaping, assembly, and packaging, enhancing efficiency and ensuring consistent quality in mass production.

What Are the Benefits of an Aluminum Bottle Production Automatic Line?

Fully Automated Spraying: Fully automated spraying systems can enhance spraying efficiency, ensuring a more uniform and consistent spraying effect. Through automation, variations in manual operations are reduced, thereby boosting production efficiency and coating quality.

Ensuring Product Quality: Automated production lines reduce human errors and variability, ensuring consistency and stability in product quality. Precise control and monitoring systems enhance production accuracy and reliability, ensuring that aluminum bottles meet quality standards.

This innovative design has been developed with enhanced convenience, functionality, customization options, and lightning-fast delivery in mind.

Automated Production: Large-size Aluminum Capsule Bottles

Last month we launched large-size aluminum jars received high praise from customers, so we opened a new aluminum capsule bottle mold.

Thanks to the fully automated production line, our bottles can do special shapes, and greatly accelerate the delivery time.

As shown in the diagram, the new line has a larger bottle size and a more specialized shape, as well as an MOQ of 50,000 pieces.

We currently offer three large sizes, 50, 53, and 59 diameters, with inner stoppers and caps purchased separately.

About Us

Hygintek is a leading manufacturer of sustainable & ECO-friendly metal packages for food & beverage, medicine, and healthy brand, offering them a one-stop package solution and service.